Screen printing and hot stamping are two key methods used when designing packaging for various types of products. The main difference between the two is that one provides a glossy image while the other presents attractive highlights.

Silk Screen Printing

This method is named for the procedure involved. Before the invention of a polyester mesh, silk was used in the process. Since one color can be used for a specific amount of time, several screens are used to produce an image or brilliant design.

The screen is made of a lattice stretched over the frame. For the mesh to be fully effective, it must be mounted on a given structure and, most importantly, it must be in a state of tension. The result of the design on the material can be determined by the different types of mesh sizes.

Screen printing can be described as a stencil method of making prints in which a specific design is imposed on a fine mesh or screen and blank areas are coated with an opaque substance. The ink is then forced through the silk and printed on the surface. Another term for this method is silk printing. It is more versatile than various other techniques or styles because the surface does not need to be printed under pressure and does not need to be flat. Screen printing can easily reproduce the details of a logo or other work of art.

Hot Stamping

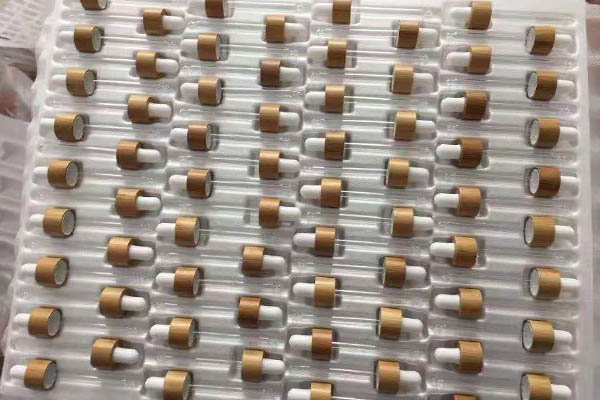

This approach is more direct than its counterpart. Hot stamping involves the process of heating foil on a packaging surface with the aid of a mold. Although it is widely used for paper and plastics, this method can be applied to other sources as well.

In hot stamping, the mold is mounted and heated, and then aluminum foil is placed on top of the package to be hot stamped. While the material is under the mold, a painted or metalized leaf-rolling carrier is placed between the two, through which the mold is pressed down. A combination of heat, pressure, retention, and peel time controls the quality of each seal. Impressions can be created from any given artwork, which may include text or even a logo.

Hot stamping is considered environmentally friendly because it is a relatively dry process that does not result in any form of pollution. It does not produce any harmful vapors and does not require the use of solvents or inks.

When the thermal printing method is used in the packaging design phase, the foil is shiny and contains reflective properties that, when illuminated, produce a shiny image of the desired artwork.

Screen printing, on the other hand, creates a matte or flat design image. Even if the ink used has a metallic substrate, it still lacks the high gloss of aluminum foil. Hot stamping provides a sense of profiteering for every custom design used in the packaging industry. Because first impressions are so important in this regard, hot stamping products can impress customers with high expectations.

SHNAYI Packaging can do both screen printing and hot stamping, so feel free to call or email us if you would like to release anything shortly.

WE’RE CREATIVE

WE’RE PASSIONATE

WE’RE THE SOLUTION

Email: merry@shnayi.com

Tel: +86-173 1287 7003

24-Hours Online Service For You

Post time: 11月-12-2022