Ushicilelo lwesikrini kunye nesitampu esishushu ziindlela ezimbini eziphambili ezisetyenziswa xa kuyilwa ukupakishwa kweentlobo ezahlukeneyo zeemveliso.Umahluko ophambili phakathi kwezi zimbini kukuba enye ibonelela ngomfanekiso omenyezelayo ngelixa enye iveza iimbalasane ezinomtsalane.

Silk Screen Printing

Le ndlela ibizwa ngegama lenkqubo ebandakanyekayo.Ngaphambi kokuveliswa kwe-polyester mesh, isilika yayisetyenziswa kule nkqubo.Ekubeni umbala omnye unokusetyenziselwa ixesha elithile, izikrini ezininzi zisetyenziselwa ukuvelisa umfanekiso okanye uyilo oluqaqambileyo.

Ikhusi lenziwe ngelathisi eyoluliweyo phezu kwesakhelo.Ukuze i-mesh isebenze ngokupheleleyo, kufuneka ifakwe kwisakhiwo esinikiweyo kwaye, ngokubaluleke kakhulu, kufuneka ibe kwimeko yoxinzelelo.Isiphumo soyilo kwizinto eziphathekayo sinokumiselwa ngeentlobo ezahlukeneyo zobukhulu be-mesh.

Ukuprintwa kwesikrini kunokuchazwa njengendlela ye-stencil yokwenza iiprinta apho idizayini ethile ibekwe kwi-mesh emihle okanye isikrini kunye neendawo ezingenanto zifakwe nge-opaque substance.I-inki ke inyanzeliswa ngesilika kwaye iprintwe kumphezulu.Elinye igama lale ndlela kukuprintwa kwesilika.Iguquguquka ngakumbi kunezinye iindlela ezahlukeneyo zobuchule okanye izimbo kuba umphezulu awufuni kushicilelwa phantsi koxinzelelo kwaye awudingi ukuba mcaba.Ukuprintwa kwesikrini kunokuvelisa ngokulula iinkcukacha zelogo okanye omnye umsebenzi wobugcisa.

Isitampu esishushu

Le ndlela ithe ngqo ngakumbi kunomlingani wayo.I-Hot stamping ibandakanya inkqubo yokufudumeza i-foil kwindawo yokupakisha ngoncedo lwe-mold.Nangona isetyenziselwa kakhulu iphepha kunye neeplastiki, le ndlela ingasetyenziswa nakweminye imithombo.

Kwi-stamping eshushu, i-mold ifakwe kwaye ishushu, kwaye emva koko i-aluminium foil ibekwe phezu kwephakheji ukuba ifakwe isitampu esishushu.Ngelixa izinto ziphantsi kokungunda, i-carrier epeyintiweyo okanye enesinyithi ehambisa amagqabi ibekwe phakathi kwezi zimbini, apho ukubunjwa kucinezelwe phantsi.Indibaniselwano yobushushu, uxinzelelo, ukugcinwa, kunye nexesha le-peel lilawula umgangatho wetywina ngalinye.Imibono ingenziwa kuwo nawuphi na umsebenzi wobugcisa onikiweyo, onokuquka okubhaliweyo okanye nelogo.

Isitampu esishushu kuthathwa ngokuba sinobuhlobo nendalo esingqongileyo kuba yinkqubo eyomileyo noko engabangeli naluphi na uhlobo longcoliseko.Ayivelisi nayiphi na imiphunga eyingozi kwaye ayifuni ukusetyenziswa kwe-solvents okanye ii-inki.

Xa indlela yokushicilela i-thermal isetyenziswe kwisigaba soyilo lokupakisha, i-foil iyakhazimula kwaye iqulethe iimpawu ezikhanyayo ezithi, xa zikhanyisiwe, zivelise umfanekiso ocwebezelayo womzobo ofunekayo.

Ukuprintwa kwesikrini, kwelinye icala, kudala umfanekiso woyilo we-matte okanye osicaba.Nokuba i-inki esetyenzisiweyo ine-metallic substrate, ayinayo iglosi ephezulu yefoyile yealuminiyam.Isitampu esishushu sinika ingqiqo yokwenza inzuzo kulo lonke uyilo lwesiko olusetyenziswa kwishishini lokupakisha.Ngenxa yokuba imbonakalo yokuqala ibaluleke kakhulu kulo mba, iimveliso zesitampu ezishushu zinokuchukumisa abathengi ngokulindela okuphezulu.

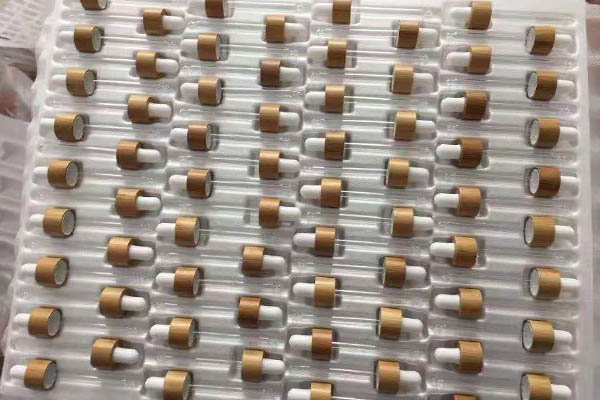

Ukupakishwa kwe-SHNAYI kunokwenza zombini ukuprintwa kwesikrini kunye nesitampu esishushu, ngoko zikhululeke ukusifowunela okanye usithumele i-imeyile ukuba ungathanda ukukhulula nantoni na kungekudala.

SIYACALA

SIYATHANDA

THINA SINGISISOMBULULO

I-imeyile: merry@shnayi.com

Umnxeba: +86-173 1287 7003

Iiyure ezingama-24 kwiNkonzo ye-Intanethi kuwe

Ixesha lokuposa: 11月-12-2022